3610 TROMMEL WASH PLANT

SPECIFICATIONS

| 3610 STANDARD & EX | SPECS |

|---|---|

| Length | Standard: 156" (3,962mm) EX: 204" (5,181mm) |

| Width | 90" (2,286mm) |

| Height | 90" (2,286mm) |

| Weight | 6,500lbs (2,949kg)- (Depending on options) |

| Scrubber Barrel Length | Standard: 48” (1,219mm) EX: 96" (2,438mm) |

| Screen Barrel Length | 60” (1,524mm) |

| Barrel Diameter | 36” (914mm) |

| Barrel Speed Fully Adjustable By Way Of On-Board VDF | 9-13 RPM |

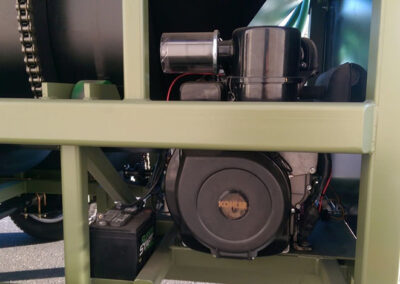

| Gas Drive System Model 3610 | Honda/Kohler/Briggs (Electric Start) Engine |

| Electric Drive System Model 3610-E | 230V - 3 Phase (50 or 60 Hz. Compatible) (3-phase/15KW Minimum generator) |

| Diesel Drive System Model 3610-I | Hatz/Yanmar/Kohler engine |

| Water Requirements | 600+ US-GPMs Preferred |

| Hopper Feed Dimensions (Dump Area) | Length: 96” (2,438mm) Width: 78” (1,676mm) Height: 12" (304mm) Grizzly bar spacing - 5” (127mm) |

| Gold Sluice Dimensions | Length: 12'L (3,657mm) as standard (With other options available) Width: 36” (914mm) |

| Optional Diamond / Gemstone Pan-American Duplex Jig | Size: 42" x 42" Capacity Y3/Hr: 20-30 See full specs below |

| Wheeled Or Skid Based Units | Available Upon Request |

| Schedule B Code | 8474.10.0010 |

PRICING

| GOLD RECOVERY | DRIVE SYSTEM | USD |

|---|---|---|

| 3610 (Standard) Includes Sluice Box | Gas | $37,500 |

| 3610-E Includes Sluice Box | Electric | $43,890 |

| 3610-I Includes Sluice Box | Diesel | $43,890 |

| DIAMOND / GEMSTONE / GOLD RECOVERY | DRIVE SYSTEM | USD |

|---|---|---|

| 3610 (Standard) Includes 30” / 762mm Pan-American Duplex Jig | Gas | $71,200 |

| 3610-E Includes 30” / 762mm Pan-American Duplex Jig | Electric | $77,590 |

| 3610-I Includes 30” / 762mm Pan-American Duplex Jig | Diesel | $77,590 |

| OPTIONS | USD |

|---|---|

| EX Model With Extended Scrubber Barrel (doubles the scrubber barrel length) | $5,900 |

| Fender Kit | $450 |

| Trailer Brakes With Lights Kit | $790 |

| Sluice Box Locking Security Screens | $1,090 |

| Extended Sluice Box (additional 24in) | $550 |

| Spare Parts Kit - Standard | $760 |

| Spare Parts Kit - EX | $820 |

PAN-AMERICAN JIG SPECS

| OPTIONAL DIAMOND / GEMSTONE PAN-AMERICAN DUPLEX JIG | SPECS |

|---|---|

| Size | 42" x 42" |

| Capacity Y3 / Hour | 20 - 30 |

| Maximum Feed Size | 1/2" |

| Concentration Ratios | 300:1 |

| Hutch Water Requirements gal/min/cell | 40 - 100 |

| Length Of Stroke (Inches) | 3/4 to 11/2 |

| Stroke Frequency | 120 - 140 |

| Ragging Bed, 3/16” Steel Shot / Cell lbs: | 400 |

| Power required (Hp) | 3 |

| Weight | 2,400lbs |

| Shipping Dimensions (W x L x H) | 46" x 88" x 66" |

The Standard model “3610” Portable Trommel is a 50+ Ton per hour Wash Plant that can be purchased as either a Gas driven, Diesel driven or Electric driven model. Included is a traditional “Gravity-Feed” style Feed Hopper (NON-Vibrating) that features a large feed area measuring in at 70″W x 96”L. This Wash Plant features a 2 stage / 2-piece – 36″ (914mm) Diameter Barrel with an overall length of 11′ (3352mm). Optional EX model has a 15’ (4572mm) barrel length.

This Wash Plant is designed for commercial mining. This unit is a versatile & mobile placer processing plant that is virtually “plug and play”. It is a self-contained, portable unit that is well suited for medium scale commercial mining. Its mobility is especially suited to move up and down the alluvial plain, moving the plant to the ore instead of excavating and hauling ore to a stationary plant. It’s designed to be easy to operate with low maintenance. It is extremely durable and dependable, perfect for hassle free service at remote locations.

This Wash Plant is offered in two different styles for either gold recovery or Diamond/Gemstone recovery.

The Gold recovery model includes a matching sluice box gold recovery system that is 12’ (3657mm) Long x 36” (914mm) Wide – different lengths available upon request.

The Diamond/Gemstone recovery model replaces the sluice box with a matched to size 42” (1066mm) Duplex Pan-American Diamond Jig recovery system.

VIDEO

GALLERY

Inside of the 8’ Scrubbing portion of the barrel of the Model 3610-EX shows sequentially spaced Slurry Turn-Plates and Dams for the best clay break down possible

Inside of the 8’ Scrubbing portion of the barrel of the Model 3610-EX shows sequentially spaced Slurry Turn-Plates and Dams for the best clay break down possible

Inside of the 4’ scrubbing portion of the barrel of the standard length Model 3610 shows sequentially spaced Slurry Turn-Plates and Dams for the best clay break down possible

Inside of the 4’ Scrubbing portion of the barrel of the standard length Model 3610 shows sequentially spaced Slurry Turn-Plates and Dams for the best clay break down possible

The Standard model “3610” Portable Trommel is a 50+ Ton per hour Wash Plant that can be purchased as either a Gas driven, Diesel driven or Electric driven model. Included is a traditional “Gravity-Feed” style Feed Hopper (NON-Vibrating) that features a large feed area measuring in at 70″W x 96”L. This Wash Plant features a 2 stage / 2-piece – 36″ (914mm) Diameter Barrel with an overall length of 11′ (3352mm). Optional EX model has a 15’ (4572mm) barrel length.

This Wash Plant is designed for commercial mining. This unit is a versatile & mobile placer processing plant that is virtually “plug and play”. It is a self-contained, portable unit that is well suited for medium scale commercial mining. Its mobility is especially suited to move up and down the alluvial plain, moving the plant to the ore instead of excavating and hauling ore to a stationary plant. It’s designed to be easy to operate with low maintenance. It is extremely durable and dependable, perfect for hassle free service at remote locations.

The standard model “3610” Trommel Wash Plant can be purchased with either a gas or diesel or electric drive system and includes an oversized gear reduction system for a long dependable service life. Final drive is adjustable between 6-13 rpms.

The Wash Plant sports a 2 stage / 2-piece – 36″ (914mm) Diameter Barrel with an overall length of 11′ (3352mm). Optional EX model has a 15’ (4572mm) barrel length. Inside the 4′ (1219mm) [EX model 8’ (2438mm)] “Scrubber” section of the barrel are sequentially spaced heavy duty slurry turn plates and dams to hold the slurry in the barrel for the best possible clay breakdown. The screen section of the barrel classifies to 1/2″ minus (other sizes available) and is 5′ (1524mm) in length giving 6,782 sq. inches (172263mm) of overall screen area – 2.5 times more screen area of other similar sized wash plants on the market. In the tail section of the barrel are two “nugget catch” rings for retention of over-sized values.

This model has 3 large spray bars that are fully adjustable and easily removable for cleaning.

Not shown is a removable long barrel discharge chute that stows for transport.

The main hopper is a traditional “Gravity-Feed” style (NON-Vibrating) and is fully adjustable in angle enabling better feed rate adjustment as well as wash duration of oversize material before discard. The hopper features a large feed area measuring in at 70″W x 96”L and the removable “grizzly” classifies to an initial size of 5″ and comes complete with two full width adjustable 2″ diam. spray bars.

All trailer based units are sold as off-road use only.

BENEFITS

Designed For Commercial Mining

Made In The USA

Best Recovery Percentages On The Market

Easy To Setup & Operate

Low Maintenance

Extremely Durable And Dependable

Perfect For Hassle Free Service At Remote Locations

Worldwide Shipping Via Sea Container

Start Mining Today!