MINI MAX-V TROMMEL WASH PLANT

SPECIFICATIONS

| Mini-Max | SPECS |

|---|---|

| Length | Standard: 119" (3,022mm) EX: 143" (3,632mm) |

| Width | 45" (1,143mm) |

| Height | 72" (1,828mm) |

| Weight | 1,200lbs (544kg) (Depending on options) |

| Scrubber Barrel Length | 48” (1,218mm) |

| Screen Barrel Length | 36” (914mm) |

| Barrel Diameter | 15” (381mm) |

| Barrel Speed | Variable |

| Electric | 208 / 240v single phase OR 3-phase (50 or 60 Hz. compatible) 7,000 watt genset minimum recommended |

| Schedule B Code | 8474.10.0010 (ships by way of pallet/crate) |

| Water Requirements | 300 US-GPMs Minimum 380+ US-GPMs Preferred |

| Vibrating Feed Hopper (dump area) | Length: 72” (1,828mm) Width: 41" (1,041mm) Height: 12" (304mm) |

| Gold Sluice Dimensions | Length: 7'L (2,136mm) standard, other options available Width: 12” (304mm) |

| Optional Diamond / Gemstone Pan-American Duplex Jig | Size: 12" x 12" Capacity Y3/Hr: 2-3 See full specs below |

| Wheeled Or Skid Based Units | Available Upon Request |

PRICING

| MODELS | USD |

|---|---|

| Gold Recovery Includes Vibrating Pan-Feeder Style Hopper | $14,570 |

| Diamond / Gemstone / Gold Recovery Includes Vibrating Pan-Feeder Style Hopper | $25,370 |

PAN-AMERICAN JIG SPECS

| OPTIONAL DIAMOND / GEMSTONE PAN-AMERICAN DUPLEX JIG | SPECS |

|---|---|

| Size | 12" x 12" |

| Capacity Y3 / Hour | 2 - 3 |

| Maximum Feed Size | 1/2" |

| Concentration Ratios | 300:1 |

| Hutch Water Requirements gal/min/cell | 5 - 10 |

| Length Of Stroke (Inches) | 3/4 to 11/2 |

| Stroke Frequency | 140 - 175 |

| Ragging Bed, 3/16” Steel Shot / Cell lbs: | 80 |

| Power required (Hp) | .5 |

| Weight | 700lbs |

| Shipping Dimensions (W x L x H) | 16" x 30" x 56" |

The Mini-Max-V Trommel Wash Plant (7+ Tons Per Hour) is the largest most efficient “Mini” trommel manufactured in the United States. This Trommel is electric drive & has a vibrating “Pan-Feeder” style hopper that features the largest feed area offered for a “Mini” style Trommel Wash Plant.

The main hopper is a vibrating “Pan Feeder” design powered by a Genuine “OLI” brand vibrating motor (identical in design to the 159-V hopper, just smaller). This design eliminates all pulleys & belts and increases durability & reliability. The vibrating feed hopper enables a better feed rate adjustment as well as a longer wash duration of oversize material before discard & is fully adjustable in angle. The “dump area” on the over sized Feed Hopper measures 72” (1,828mm) long x 41” (1,041mm) wide and 12” (304mm) deep. The classification “grizzly” is set to an initial size of 2.5” (63.5mm). The hopper comes complete with two full width adjustable 2″ diameter spray bars located directly above the classification grizzly and two additional spray bars that run the length of the sides in the dump area of the hopper. There are five spray bars total for this unit and they are each set on their own gate valves for the ultimate in water flow adjustment. The water distribution box also has a connection for a wash out hose.

This Wash Plant is offered in two different styles for either gold recovery or Diamond/Gemstone recovery.

The gold recovery model includes a matching sluice box gold recovery system that is 7’ (2,136mm) long x 12” (304mm ) wide. Different lengths available upon request.

The Diamond/Gemstone recovery model replaces the sluice box with a matched to size 12” (304mm) Duplex Pan-American Diamond Jig recovery system.

VIDEO

GALLERY

Mini-Max-V-EX with OPTIONAL EXTENDED SCRUBBER BARREL Model shown with hoses for use with chemicals and explosion proof motor and vibrator for a custom project for a client.

Vibrating Feed Hopper is fully adjustable in angle. The weights for the vibrator as well as the speed of the vibrator are adjustable as well to fine tune material feed rate.

This wash plant is an extremely portable and versatile unit that can be towed behind an ATV. The unit has a wide stance and good center of gravity with good ground clearance due to the 4ct. ATV tires which are on an articulating Cantilever style axle which is perfect for difficult terrain. The tow bar is removable by pulling a single 1/2 inch hitch pin. The Mini-Max-V can be easily set up and ready to run in a matter of minutes. The legs are fully adjustable in height to compensate for varying terrain & also to adjust material processing rates.

The standard length Mini-Max-V can be loaded into/out of a standard truck bed or trailer. The all steel frame is fully triangulated for maximum durability while still remaining light weight.

This Wash Plant is powered by an electric drive system, capable of operating with a small generator (7,000 watt+) and can be used with either 50 Hz. Or 60 Hz. 208V/220V/230V Single phase (OR with a 3-Phase power supply upon request).

The Standard 2-stage barrel is 8 foot in total length and 15 inch in diameter. The Standard “Scrubber” section of the barrel is 48”/1219mm in length (optional EX model has a 72” (1,828mm barrel length). The Barrel is loaded with a full array of slurry “turn plates” (material lifting bars) as well as slurry dams, both of which enable excellent clay and cemented gravel break down and washing. This unit has the largest and best working “Scrubber” section available for a unit this size and helps level out the material “surging” that is common with shorter barrels.

The screen portion of the barrel is 36 inch in length and is manufactured from perforated steel (punch plate) with the highest percentage of “open area” available to help produce some of the highest “Tons per Hour” numbers available to the open market. Classification hole size is 1/2-inch standard with other sizing options available upon request. The tail section of the barrel contains two of our “Nugget rings” for retention of oversized values.

The motor comes with a heavy-duty skid plate underneath. The over-sized positive chain drive system utilizes sealed unit bearings and is fully adjustable in tension both at the motor as well as the barrel. This setup provides a long dependable service life. Final drive is 10-rpms.

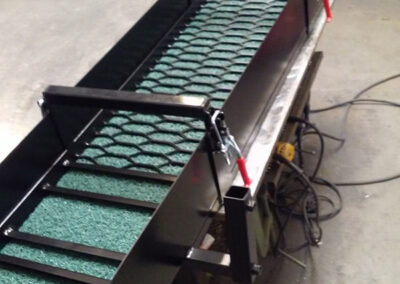

The included sluice box gold recovery system measures in at 7’ (2,136mm) long by 12” (304mm) wide and is more than adequate at keeping up with the feed rate associated with this Trommel Wash Plant. Standard riffle design is a “70/30” mix of 3# Gratex (large expanded) and Hungarian style riffles that have varied spacing and angles to ensure great recovery percentages of values.

We can also custom tailor the sluice recovery system to the specific recovery needs of your particular operation as well.

Also included with the sluice is one of our infamous 2′ long “Raised Slick-Plates” to provide a smooth flow transition to the riffles which increases recovery #s. The sluice comes with a full square tube “ladder” style frame and fully adjustable legs to enable ease of adjustment of sluice angle. When setting up for operation, the sluice can be mounted on either side of the Trommel unit with a single 3/8-inch grade 8 quick release mounting pin which allows for ease of adjustment to most any angle.

BENEFITS

Designed For Commercial Mining

Made In The USA

Best Recovery Percentages On The Market

Easy To Setup & Operate

Low Maintenance

Extremely Durable And Dependable

Perfect For Hassle Free Service At Remote Locations

Worldwide Shipping Via Sea Container

Start Mining Today!

![Mini-Max-V-EX [OPTIONAL EXTENDED SCRUBBER BARREL Model]](https://hecklerfabrication.com/wp-content/uploads/2023/10/Heckler-Fabrication-Mini-Max-V-Trommel-Wash-Plant-13-400x284.jpg)

![Mini-Max-V-EX This is the OPTIONAL EXTENDED SCRUBBER BARREL Model we offer [Model: Mini-Max-V-EX]](https://hecklerfabrication.com/wp-content/uploads/2023/10/Heckler-Fabrication-Mini-Max-V-Trommel-Wash-Plant-11-400x284.jpg)